Radiant heating ceiling panels are increasingly popular for industrial settings, due to their efficient heating capabilities and energy savings. That heating system uses infrared radiation to provide warmth to the room, and can offer numerous benefits over traditional systems. In that blog post, will explore the advantages of using radindustrial infrared heating panels, and how they can help you maximize efficiency and reduce costs.

What Are Infrared Heating Panels And Systems?

Infrared heating panels and systems are a type of heating system that utilizes infrared radiation to provide warmth to industrial settings. Unlike traditional heating systems that rely on convection or forced air, these panels emit radiant heat directly to objects and surfaces in the room, which then absorb and radiate the warmth, creating a more efficient and comfortable heating solution.

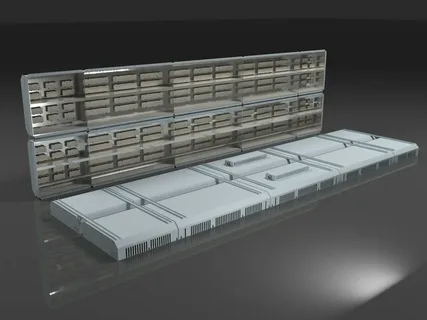

The panels are typically mounted on the ceiling, allowing for even heat distribution throughout the space. They comprise heating elements that generate infrared radiation when electricity passes through them. That radiation is emitted into the room, providing direct and immediate warmth.

Provide Health and Safety Benefits

These heating systems also provide health and safety benefits. Unlike forced air systems that can circulate dust and allergens, radiant heat does not disturb the air, reducing the risk of respiratory issues. Furthermore, the absence of moving parts and using electricity instead of gas make them safer and cleaner alternatives.

Regarding maintenance and longevity, infrared heating panels require minimal upkeep. They have no moving parts that can break down, and their solid construction ensures durability. That means lower maintenance costs and longer lifespan compared to traditional systems.

Overall, infrared heating panels and systems are a cost-effective, energy-efficient, and safe solution for heating industrial spaces. They offer numerous benefits, making them an excellent choice for maximizing efficiency and reducing costs in industrial settings.

Advantages of Industrial Infrared Heating Systems

Industrial infrared heating systems offer numerous advantages over traditional heating systems in industrial settings.

One of the key advantages is their energy efficiency. Unlike conventional heating systems that heat the air, infrared heating systems directly emit radiant heat onto objects and surfaces in the room. That direct heating method eliminates energy wastage by heating the air, resulting in lower energy consumption and reduced heating costs.

In addition to energy efficiency, infrared heating systems provide a more even temperature distribution throughout the space. The heat is emitted from the ceiling, ensuring no cold spots or drafts in the room. That creates a comfortable and consistent heating solution for industrial settings.

Lower Maintenance Costs

These heating systems offer health and safety benefits. Unlike forced air systems that can circulate dust and allergens, radiant heat does not disturb the air, reducing the risk of respiratory issues. Additionally, infrared heating systems have no moving parts and use electricity instead of gas, making them safer and cleaner alternatives.

Maintenance and longevity are also advantages of infrared heating systems. With minimal upkeep and no moving parts that can break down, these systems have lower maintenance costs and longer lifespans than traditional heating systems.

Overall, infrared heating systems provide a cost-effective, energy-efficient, and safe solution for heating industrial spaces. Their advantages make them an excellent choice for maximizing efficiency and reducing costs in industrial settings.

Energy Efficiency of Radiant Ceiling Heat

Infrared heating panels offer exceptional energy efficiency compared to traditional heating systems. The key to their efficiency lies in their direct heating method. Unlike conventional systems that heat the air, radiant ceiling heat panels emit infrared radiation directly onto objects and surfaces in the room.

By targeting objects and surfaces, ceiling heat panels provide rapid and direct warmth to the space, without preheating. That instant heat delivery ensures maximum efficiency, as there is no heat loss during the transfer from the heating source to the room.

Even Temperature Distribution

Radiant heat panels also provide an even temperature distribution throughout the space. The heat radiates from the ceiling, eliminating cold spots and drafts. That ensures a comfortable working environment and minimizes the need for additional heating sources or supplementary heating, further reducing energy consumption.

Overall, the energy efficiency of ceiling heat panels can lead to significant cost savings for industrial settings. With lower energy consumption and reduced heating costs, businesses can maximize efficiency and allocate resources to other areas of operation.

Health and Safety Benefits of Ceiling Heating Panels

Ceiling heating panels provide efficient and cost-effective heating solutions for industrial settings and offer significant health and safety benefits. Unlike traditional forced air systems that circulate dust and allergens, radiant heat from ceiling panels does not disturb the air, reducing the risk of respiratory issues for employees.

The absence of moving parts in heating panels makes them safer than other heating systems. There is no mechanical failure or malfunction risk, which can pose potential hazards in industrial environments. Additionally, since ceiling panels use electricity instead of gas, no combustion is involved, eliminating the risk of gas leaks or emissions.

Smart Choice for Industrial Settings

Another advantage of heating panels is their clean and dust-free operation. Unlike forced air systems that can stir up dust and particles, radiant heat panels do not disturb the air, making them ideal for industries that require a clean and controlled environment.

Furthermore, the even temperature distribution provided by heating panels eliminates cold spots and drafts in industrial spaces. That not only ensures the comfort of employees but also helps to prevent injuries or health issues related to exposure to cold or uneven temperatures.

Overall, heating panels’ health and safety benefits make them a smart choice for industrial settings, providing a comfortable and safe working environment while minimizing potential health risks and hazards.

Maintenance and Longevity of Heating Panels

Regarding heating systems in industrial settings, maintenance and longevity are important factors. Fortunately, radiant ceiling panels excel in both areas. These panels are designed to require minimal upkeep, making them a cost-effective and hassle-free choice for heating industrial spaces.

One of the key advantages of radiant ceiling panels is their lack of moving parts. Unlike traditional heating systems that rely on mechanical components that can break down, these panels are solidly constructed and built to last. With no moving parts to worry about, you can expect fewer repairs and lower maintenance costs over time.

In addition to their durability, heat ceiling panels are designed for easy installation and replacement. That means that if a panel does need to be replaced, the process is quick and straightforward, minimizing downtime and disruption to your operations.

Built To Withstand the Demands of Industrial Environments

Furthermore, the solid construction of these panels ensures their longevity. They are built to withstand the demands of industrial environments, meaning they won’t deteriorate or wear out easily. With proper care and maintenance, heat ceiling panels can provide reliable heating for many years.

Overall, the maintenance and longevity of heat ceiling panels make them a smart investment for industrial settings. They offer a hassle-free heating solution that requires minimal upkeep, allowing you to focus on your core operations while enjoying the benefits of efficient and cost-effective heating.

Installation Process of Radiant Heat Ceiling Panels

Installing radiant heat ceiling panels in industrial settings is a straightforward and efficient. Here is a step-by-step guide to help you understand the installation process.

Preparing the space

Before installation, ensure the ceiling is clean and free of any obstructions. Clear the area where the panels will be installed to provide easy access and ensure proper positioning.

Determining panel placement

Plan the placement of the panels to ensure even heat distribution throughout the space. Consider the size of the room, the layout, and specific heating requirements. Consult with a professional to determine the optimal placement for maximum efficiency.

Electrical connections

Connect the panels to a power source. It is recommended to hire a licensed electrician to ensure proper wiring and adherence to safety regulations.

Testing and calibration

Test the system to ensure proper functioning once the panels are securely mounted and connected. Adjust the temperature settings and calibration if necessary.

Savings on Operating Costs with Ceiling Heat

Radiant heated ceiling panels offer significant savings on operating costs for industrial settings. Their energy-efficient design and direct heating method result in lower energy consumption and reduced heating costs compared to traditional systems.

By emitting infrared radiation directly onto objects and surfaces, ceiling heat panels eliminate the need to heat the air, which can be a major energy drain. That targeted heating approach ensures energy is used efficiently, saving business costs.

FAQs

Q: How Do Radiant Heat Ceiling Panels Work?

A: Radiant heat ceiling panels work by emitting infrared radiation directly onto objects and surfaces in the room. The objects absorb infrared radiation, creating warmth in the space.

Q: Are Radiant Ceiling Panels Safe?

A: Yes, radiant ceiling panels are safe in industrial settings. They have no moving parts and use electricity instead of gas, eliminating the risk of mechanical failure or gas leaks. Additionally, radiant heat panels do not disturb the air like forced air systems, reducing the risk of respiratory issues.

Q: How Do Radiant Ceiling Panels Benefit Industrial Settings?

A: Radiant ceiling panels offer numerous benefits to industrial settings. They provide energy-efficient heating by directly emitting infrared radiation onto objects and surfaces, eliminating energy wastage. These panels also offer even temperature distribution, eliminating cold spots and drafts.

Q: What Industries Can Benefit From Radiant Ceiling Panels?

A: Radiant ceiling panels are suitable for various industries. They are commonly used in warehouses, distribution centers, manufacturing facilities, and automotive garages. They provide efficient and cost-effective heating solutions, ensuring comfortable working environments while maximizing energy efficiency.

Q: Can Radiant Ceiling Panels Be Easily Installed?

A: Yes, radiant ceiling panels are designed for easy installation. They typically require minimal preparation and can be mounted securely onto the ceiling. It is recommended to consult with a professional for optimal panel placement and to ensure proper electrical connections.

Q: How Do Radiant Ceiling Panels Save On Operating Costs?

A: Radiant ceiling panels offer significant savings on operating costs. They are energy-efficient, resulting in lower energy consumption and reduced heating costs. Their low maintenance requirements and long lifespan also contribute to further cost savings.

Q: Can Radiant Ceiling Panels Be Used With Other Heating Systems?

A: Radiant ceiling panels can be used as a standalone heating system or in conjunction with other heating systems, depending on the specific needs of the industrial setting.

Conclusion

Radiant ceiling panels are a game-changer when heating industrial spaces. They offer numerous advantages over traditional heating systems, including energy efficiency, even temperature distribution, health and safety benefits, and low maintenance requirements. Radiative heat ceiling panels eliminate energy wastage and reduce heating costs by utilizing infrared radiation to provide direct and immediate warmth. They also create a more comfortable working environment by eliminating cold spots and drafts. In terms of health and safety, these panels are a safe and clean alternative to forced air systems.